|

www.thundervalleyracing.com

|

|

Talking About Tires |

|||||||||||||||

|

Part

6 of a series of technical articles

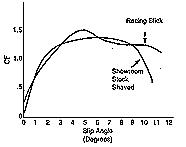

Race cars today use many different types of tires, from long lasting DOT street tires in showroom stock, to sticky slicks that are useful for just two or three laps in qualifying open wheel racers. Still, all of these different tires have basic properties in common. Rubbers, polymers, oils and carbon are combined into a black goo that is reinforced with steel and nylon and molded into a round shape. This form is then cured under pressure (vulcanized) with sulfur to bond the molecules together. A tire is created! No tire engineer will divulge the formula for this creation, and they are constantly working to produce the next generation of stick.

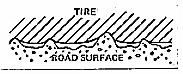

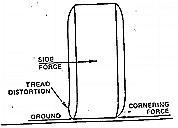

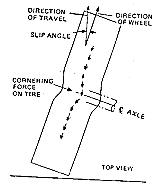

All tires grip the road through the molecular bonding of rubber and road surface. As a tire rolls freely across the road surface, for each brief moment, there is one to one contact of rubber to road. This is the contact patch. The total size of this patch for all four tires combined is approximately one square foot of rubber. It is rare for the car not to be affected by some force - wind, contour of the road, or load transfer. Friction is produced when resistance to the tire’s motion is generated by a load pushing down on it. The numerical value given to this ratio of resistance to load is the Coefficient of Friction. It is a measurement used to compare different tires or the same tire with different set up specs. A tire with a higher CF will be grippier than a tire with a lower CF value. All race car set-up starts with tires! Let’s see what tires can do. Tires have three capabilities: 1) accelerating grip; 2) decelerating (braking) traction; and 3) cornering force. The small area of rubber, the contact patch, does all this work. In either straight line acceleration or braking, when no other demands are made on the tire, all the tire’s traction can be used for the one function. Slip in this longitudinal motion is measured as a percentage. Maximum percent slip is around 15%. In everyday driving this slip is not used, but when trying to find the extra tenth on track, recognizing the limits of adhesion and balancing the car on these limits produces fast lap times. When braking into a corner, reduction of wheel speed by 15% gives maximum traction for turn in. Push on the pedal too hard and the tire loses too much of its traction and the car will slide. Still more pressure and the brakes will lock and flat spot the tires. On corner exit, too heavy on the throttle can generate wheel spin, not traction. Coordinating power on and the feeling for grip gives maximum acceleration out of the corner and down the straight. When the contact patch is distorted, under cornering loads, the tire is pulled away from the direction that the wheel is pointing. This is referred to as slip angle. The slip angle is a measurement of the direction of steering input verses the direction the tire is going. If you compare the two directions you would get the degree of a radius of a circle.

Up to a given degree of distortion the tire will have grip, after that the tire begins to slide. At this point the car is at its limits of adhesion and is producing maxim CF. Being sensitive to slip allows the driver to know what the car is doing and to drive up to these limits.

When the tire needs to do more than one function at a time - braking and turning, acceleration and turning - the tires are asked to share the work load. To chart these forces Mark Donahue developed the concept of a traction circle. My next article will deal with this concept in greater detail. Here is where tires are asked to do most of the work.

In slip the tire has grip. We feel this pulling force on the steering: small force, small slip angle; maximum force, large slip angle (limit of adhesion). Then when the slip angle becomes too great, the tire will break away and slide. Recognizing the feeling in the steering wheel as the slip angle changes is the difference between driving the car quickly and racing. Driving at large slip angles creates a lot of resistance to the forward motion of the car. Knowing this, the driver can use the scrub created as the tire pulls sideways from the road surface to slow down in a corner without using the brake. But too much sliding, while it may look dramatic, is not fast when speed is scrubbed to keep you on line. Slip angle at the front of the car differs from slip angle at the rear of the car. There are many reasons for this, including tire sizes, weight distribution and alignment (which will be discussed in subsequent articles). When the slip angle in front is greater than the slip angle in the rear, the result is understeer. When the slip in the rear is greater it is oversteer. When the tire loses grip, the car spins and slip angle is no longer a consideration.

My intention for this series of articles is to present racing tech issues simply, in a way that will bridge your feel for what your car is doing to an understanding of why it is doing it. There is no substitute for doing. Look at your tires! Check for even wear across the surface. Check the sidewalls for signs of rolling. Check pressures. And check for cuts, chunking, and blisters. Clean off debris. Remember, everything you do to control the race car, to speed up, to slow down, and to turn, depends on four small patches of rubber and air. |

|

Home

| Member Area

|Meet the Racers

| Features | News Articles

Sponsorship

| Press Room

| Resources

| About Us

| Contact Us

|